Playing a major role in the 5G era! The TAHQ polyimide monomers expected to be used for high-frequency circuit boards

【CAS No.】2770-49-2

【Chemical Name】5,5′-[p-Phenylenebis(oxycarbonyl)]diphthalic anhydride

【Chemical Code】C24H10O10

Manac manufactures resin raw materials (monomers) known as polyimides. Polyimides excel in various properties, including strength and heat resistance, making them highly versatile.

This article introduces the TAHQ, a polyimide monomer for which Manac has just commenced mass production. TAHQ is a monomer expected to play an important role in society as IT continues to advance. Let’s look into the secrets behind this.

contents

What are polyimides?

Resins such as polyimides are formed with a long chain of small compounds called monomers.

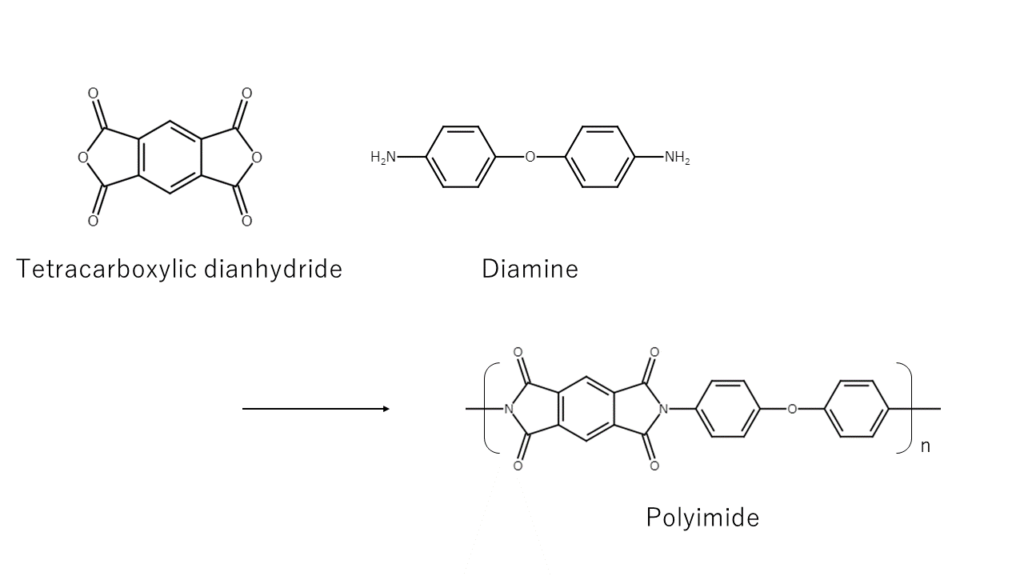

Polyimide resins are formed by bonding, in alternation, two types of monomers called tetracarboxylic dianhydrides and diamines, such as those shown below. There are various types of both tetracarboxylic dianhydrides and diamines, and the resulting polyimide structure changes depending on the monomers used (the reaction formula below is one example).

TAHQ at the pinnacle of Manac’s technical prowess

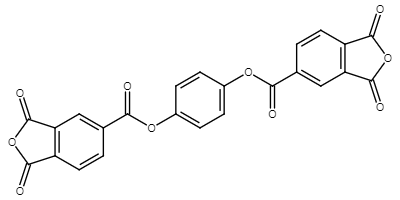

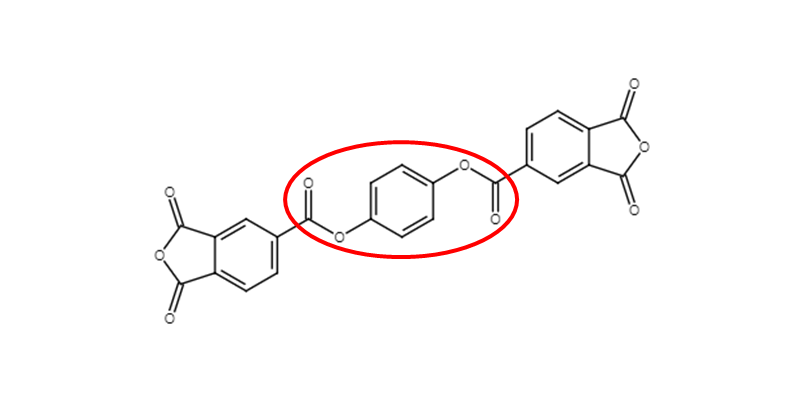

The diagram above illustrates the structure of TAHQ. The defining feature lies within the benzene ring and the two ester bonds (-COO-) that sit in the center (circled in red in the diagram above).

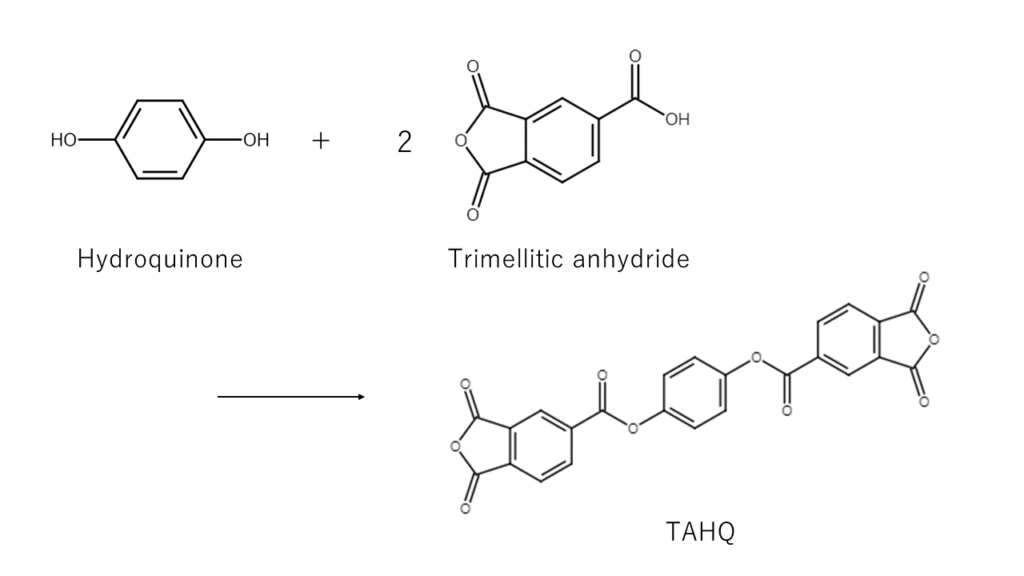

TAHQ is formed by bonding one molecule known as hydroquinone with two molecules known as trimellitic anhydride.

The above reaction formula may appear simple, but in reality, this reaction is anything but straightforward.

For example, there are cases in which the single hydroquinone molecule will only react with one trimellitic anhydride molecule, making it difficult to form TAHQ.

This reaction is called esterification (a reaction that forms an ester bond), and there is a problem in which some of the reaction products achieved from such esterification reactions (TAHQ in this case) revert to their reactants (hydroquinone and trimellitic anhydride in this case).

In order to manufacture TAHQ, a high level of technical capabilities is required to control the reaction, such as temperature and pH regulation and the selection of solvents. Manac has already established its TAHQ mass production techniques, and has constructed facilities capable of manufacturing hundreds of kilograms of TAHQ at once. The only company that carries out the commercial production of TAHQ in Japan is Manac, and only about one other company in the entire world.

The low water-absorption rate of polyimides made with TAHQ

The defining characteristic of polyimides made with TAHQ (TAHQ polyimides) is a low water-absorption rate.

While general polyimides have a water-absorption rate of up to around 3%, TAHQ polyimides have an impressive absorption rate of less than 1%. This means that TAHQ has less than 1/3 of the water absorption rate of general polyimides. It is believed that this results from the characteristic structure (benzene ring + ester bond) in the center portion of TAHQ.

The water-absorption rate of a material impacts the electrical attributes of that material. A high water-absorption rate translates to, for example, the material absorbing moisture from the air and easily allowing moisture to enter into the interior of the material. In general, moisture present in electronics materials does not have a positive impact on electrical attributes. Polyimides that use TAHQ have a low water-absorption rate, and thus possess attributes that are resistant to the impacts of moisture (permittivity and relative permittivity discussed below).

Expectations behind TAHQ’s use in high-frequency flexible circuit boards

There are expectations for utilizing TAHQ polyimides in 5G flexible (bendable like film), high-frequency circuit boards.

With digitalization advancing in the world, telecommunications companies are already starting to offer services for 5G (fifth-generation mobile communication systems). As 5G needs to deliver faster transmissions of a larger amount of data than previous generations, the technology requires high-frequency circuit boards that can quickly process signals.

Permittivity or relative permittivity is particularly crucial for high-frequency circuit boards. Lower values for this measure indicate a lower impact on the signal in the board. Generally, materials with a low water-absorption rate can lower the permittivity or relative permittivity value.

Flexible circuit boards made with traditional polyimides are considered unfit for use with high frequencies as the high water-absorption rate hinders the ability to achieve satisfactory performance. Therefore, the low water-absorption rate of polyimides made with TAHQ has resulted in expectations for their use.

In actuality, when looking at permittivity or relative permittivity alone, materials known as liquid crystal polymers are superior to TAHQ polyimides. However, switching the material used for components that have so far been made from polyimides over to liquid crystal polymers would require that all circuit board manufacturing equipment be replaced. In contrast, replacing the material used to TAHQ, which is also a polyimide, would likely not require large changes to manufacturing infrastructure. This is another advantage to using polyimides that use TAHQ.

A bright future for TAHQ

Although polyimides made with TAHQ are more expensive than traditional polyimides and other such materials, TAHQ polyimides match that price with performance.

TAHQ can be used to manufacture polyimides that excel in dielectric performance and play an important role in the 5G era. Manac will continue to focus on manufacturing and marketing TAHQ.