A world-class advantage – Moving toward waste liquid recycling / The secret behind realizing MANAC’s high-quality, low-cost DAIB

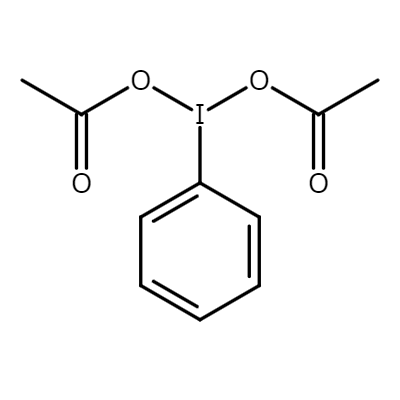

【CAS No.】3240-34-4

【Chemical name】

(Diacetoxyiodo)benzene

【Chemical formula】C10H11IO4

For over a decade, MANAC has been manufacturing and marketing DAIB, a compound used in manufacturing processes for active pharmaceutical ingredients (APIs). While MANAC offered high-quality DAIB, its high costs presented marketing hurdles.

Then, in 2021, after receiving requests from API manufacturers in Japan, MANAC set out to enhance its manufacturing method in order to achieve high-quality, low-cost DAIB. However, the development process brought one struggle after another during efforts to improve quality, including issues of byproduct impurities that were even more explosive than the conventional product itself, as well as failed attempts to increase product purity. Nevertheless, owing to the patient, persistent dedication of MANAC researchers, the team succeeded in enhancing the company’s DAIB manufacturing method.

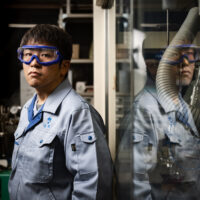

This article picks up from where we previously left the story. Will clients accept the DAIB made using MANAC’s new and improved manufacturing method? What other obstacles await the MANAC team further along the way? We met with Go Tanaka of DAIB sales and Chihiro Enmei, head of experiments for the DAIB manufacturing improvement project, to learn more.

contents

Receiving client lab approval only to hit a new brick wall

MANAC successfully established a new and improved DAIB manufacturing method. But this was only the beginning. Now, the question was whether this newly achieved DAIB would truly stand up to the quality requirements of client manufacturers.

To confirm the quality of the new DAIB, Mr. Tanaka submitted small samples to a domestic Japanese API manufacturer, a MANAC client, for lab evaluation. Mr. Tanaka explains that, after waiting some time, he was relieved to learn that the lab evaluations approved the samples.

“We were extremely pleased to find out that our new DAIB was of higher quality than our conventional DAIB, and that its reactions yielded strong results. Knowing that MANAC’s technological excellence had been recognized was deeply moving. Also, the client explained that since they would be able to use the new DAIB in actual manufacturing, they would like to place a large-scale order.”

However, amid such favorable development, a certain issue surfaced.

The samples provided to the API manufacturer for evaluation were only produced experimentally on a small scale. To handle a large-scale order, MANAC would need to ensure that the new DAIB could be safely manufactured in large quantities at a time.

Awaiting the MANAC team was an enormous brick wall that stood between them and achieving mass production.

Finding drying solutions for large-scale manufacturing and taking large strides toward expanded sales

There are fundamental differences between small-scale and large-scale manufacturing processes. Since DAIB is provided to client manufacturers as a powder product, the DAIB obtained from the reaction solution at the end of the manufacturing process must be dried. The method used for drying differs depending on the manufacturing scale.

Since small-scale manufacturing produces small amounts of DAIB, the resulting DAIB can be divided into small portions and gradually added to a small vessel. Here, DAIB undergoes shelf-type air drying, where wind is applied at relatively low temperatures over an extended period to evaporate the solvent until all of the produced DAIB has been added to the small vessel and dried. However, to efficiently dry DAIB when produced in large quantities, it must be prepared with heat and rotation under reduced pressure using a large vessel in a process known as conical drying.

While necessary, placing DAIB in conical drying involves substantial risks. Conical drying can be compared to drying a powder in a front-loading laundry dryer. Since hypervalent iodine compounds like DAIB present an explosion risk, the properties of such compounds must be identified in detail and effectively managed. In particular, because heating is needed to reduce drying times, a multifaceted evaluation of the compound’s thermal behavior, explosion sensitivity/explosive power, and management of high-risk impurities would be indispensable for gaining absolute confirmation that the new DAIB could be handled safely.

If it turned out that the new DAIB could not undergo conical drying, the manufacturing costs of the new DAIB may prove economically unviable, which could prevent expanded DAIB sales. It was up to Chihiro Enmei, head of DAIB experiments, to overcome this challenge.

Mr. Enmei explains further: “In order to determine whether we could use conical drying for the new DAIB, we enlisted the help of a third-party organization to conduct multifaceted evaluations on its explosiveness. I was worried about how the evaluations would go, but in the end, we were able to get results confirming that the new DAIB had ‘no risk of explosion if tightly controlled.’ This was a major factor behind deciding whether we could expand sales of the new DAIB as a MANAC product, so these results were a great relief.”

Growing recognition at the factory level as well

In April 2023, MANAC successfully started large-scale manufacturing of its new DAIB using conical drying. The aforementioned API manufacturer that provided lab evaluation reported using the new DAIB it purchased from MANAC for API manufacturing at its factories. According to Mr. Tanaka, the new DAIB appears to be performing strongly.

“The API manufacturer was incredibly pleased, saying that our new DAIB achieved better reactivity over DAIB from other companies. We’ve received feedback commenting that the reliably consistent quality of our DAIB opens up the possibility for improved productivity. Being highly recognized not only at the lab but also at the industrial level has given us impetus to work toward expanding DAIB sales.”

A world-class advantage – Moving toward recycling services for reaction byproducts

It may not be apparent, but MANAC is not limited to solely “making and selling” DAIB. The company also aims to provide services in the future to collect and recycle the iodine components (iodobenzene or iodine) that occur as reaction byproducts after using DAIB as an oxidant.

“Iodine, which DAIB contains, is a valuable resource produced here in the resource-scarce country of Japan, and so it is crucial that we make effective use of this limited resource. Since the iodobenzene discharged as a reaction byproduct is also a raw material of DAIB, it can be recycled into DAIB again if sufficiently collected and purified. Achieving such collection and purification would enable us to realize cyclical manufacturing processes together with our DAIB-consuming client manufacturers. These recycling services aim to accept byproducts as iodine sources, providing clients with the tremendous benefit of eliminated waste disposal needs.”

DAIB recycling services will benefit both the global environment and clients in many ways. Mr. Tanaka expresses firm confidence in our strengths, including its ability to offer such a promising service.

“The nature of the byproducts produced after DAIB usage depends heavily on the reaction conducted by the client. Of course, this means there are many cases in which iodobenzene cannot be easily collected and reused from the end byproducts. For this reason, in order to offer a recycling service that would earn client satisfaction, we need to prepare an alternative solution. Because MANAC also works in partnership with iodine manufacturers, we can collect byproducts not only in the form of iodobenzene but also in the form of iodine itself. Applying a synergy of MANAC’s pretreatment technologies with the collection technologies of iodine manufacturers based on the composition of each byproduct liquid should allow us to handle even the most challenging collection needs. A solid partnership between clients, MANAC, and iodine manufacturers would allow us to collect byproducts in a wide variety of forms, enabling MANAC to provide a clear world-class advantage.”

Having overcome many obstacles, MANAC is now working to introduce its high-quality, low-cost DAIB into the market. We expect to see the new DAIB increasingly adopted for many applications, from pharmaceuticals to electronic materials and semiconductors.

MANAC will continue striving to manufacture, market, and recycle DAIB.