Cross-contamination prevention and IT adoption led by the Idea Man/ Projects to increase production capabilities for fine chemicals

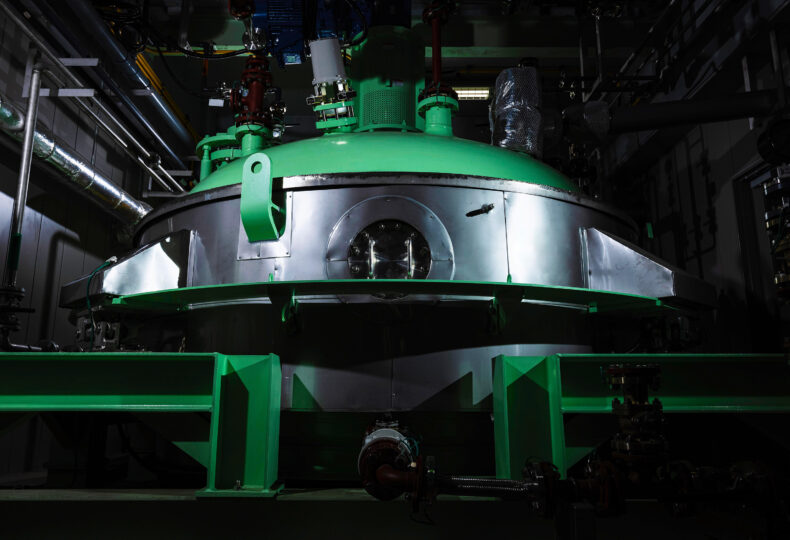

In spring 2021, new reaction facilities were introduced into Manac’s fine chemical production line. This is an achievement of a facilities renovation project planned for Manac to survive with the changing times.

This project also advanced initiatives for cross-contamination prevention and the adoption of IT systems. To learn more, we met with Mr. Masaru Mori, leader of this project and head of the Facilities Division of the Fukuyama Factory. Mr. Mori planned and directed this project. Behind his soft-spoken story, we caught a glimpse of the face of a pioneer.

■ What you can learn from this article ✔ Manac renovated the production line to increase its fine chemical production capacity. ✔ Zoning was introduced within the factory to prevent cross-contamination. ✔ IT systems were adopted, enabling equipment visualization and remote operation via tablets. ■ Recommended Articles ・ Full-scale launch of Manac’s Shonan Lab to develop original technologies and products / Aiming to identify needs and develop Manac’s technologies ・ Opportunities await us in the bromine and iodine domains / Manac’s growth strategy as told by President Murata

contents

Renovating a part of the fine chemicals production line to increase production capabilities

Manac carries out contract manufacturing for chemical intermediates in the fine chemicals field.

Fine chemicals are chemical products with a high added value produced from high-mix, low-volume (HMLV) productions to match specific applications and purposes. The fine chemicals that Manac handles are mainly chemical intermediates for items such as pharmaceutical products and electronic materials. To date, Manac has produced a large number of products.

However, several years ago, among a continuously growing demand, Manac’s fine chemicals production line was approaching the limits of its capacity, particularly for pharmaceutical-related production lines. This made it difficult to take on new contract manufacturing requests from clients. At this time, it was Mr. Mori who was contemplating solutions for the Fukuyama Factory.

“Around 2016, there was a proposal to construct a new entire factory building in order to expand the production capacity. Various constraints later led to the proposal being dropped, but I had continually been working on an idea related to renovating the factory from around that time.” Around 2019, the subject of expanding production capacity arose again at Manac. The plan this time involved renovating a section of the fine chemical factory’s production line. Mr. Mori and his team would renovate the production line through such measures as optimization. The new plan came into effect in April 2021.

Mr. Mori and his team actively engaged in initiatives for cross-contamination prevention and IT systems adoption for this renovation.

Implementing zoning within the factory to prevent cross-contamination

The divisions between each of Manac’s factory facilities are insufficient, and many factories also lack outer walls.

“Clients in the fine chemicals field are growing more demanding of facilities by the year. The demand from clients for chemical intermediates manufactured in environments with a low possibility of cross-contamination is also growing. Manac will end up being weeded out as a company if it lags behind such changes in society. With that, we drew up plans to establish clear zoning areas in the factory to prevent cross-contamination.” Adopting IT systems: Introducing mobile devices to enable equipment status confirmation, visualizations, and remote operation from anywhere.

One more key concept is “IT systems adoption.”

Manac’s factories are places where artisans’ work shines. However, in recent years, the factories of major corporations have actively been advancing their adoption of IT systems. Mr. Mori has continued considerations regarding catching up to this development.

“I’ve collected a lot of various information and thoroughly considered technologies that we might be able to introduce into Manac’s factories.” Wi-Fi-connected tablets were introduced as a part of the renovation. With the introduction of these mobile tablets, the visualization of equipment status, portable data, and production equipment operations have become possible.

In manufacturing, process data, such as temperature, is important.

Up until now, manufacturing data could only be viewed in specific areas within Manac’s factories. This resulted in several inconvenient aspects, such as workers needing to check data before starting the task and then go to the task area and not be able to check the data while carrying out the task.

“Now with the mobile tablets, the status of equipment operations and process data can be carried around and confirmed from anywhere in the factory from the tablets. Since you can check data anywhere with a tablet, the inefficient need to move between specific areas has been eliminated, and work efficiency has been vastly improved,” explains Mr. Mori.

With consideration to reducing labor, the tablets also enable remote operations. Furthermore, stationary personal computers have also been installed in the monitoring office, enabling remote operations from there as well. “We introduced portable tablets based on my firm convictions, but I am quite relieved by the growing popularity among workers.”

IT adoption plans for future facilities as envisioned by Mr. Mori

IT adoption does not end here. Mr. Mori is already working on subsequent plans.

“I would like to increase the number of sensors that can be operated from the portable tablets and achieve facilities that can further reduce the labor load. Also, since we have started collecting operations data in April, we are advancing preparations for a probable future era where we treat the collected data as big data to be partially analyzed by AI, which will then control reactions. It would also be interesting to change operation manuals from paper materials to videos that you watch on the tablets. I have a lot of ideas.”

Mr. Mori also believes that the adoption of IT systems will lead to the diversification of personnel.

“When I joined Manac, I was told to ‘learn from watching your more experienced colleagues from behind,’ and inherited the artisan knowledge that had been passed on to them in the same way. But times have changed. It is now crucial to build a system that anyone can operate, including younger workers and non-Japanese workers. Automating artisan techniques using IT is extremely vital in a continually diversifying society.”

Manac will remain a company that serves the current times

In this coming era, companies that continue their old ways cannot survive. Here at Manac, we will continue advancing innovations in line with the current times and manufacturing/developing high-quality products in order to meet various needs for the manufacture of chemical intermediates.