Aiming to provide the next option in cases unsuitable for DAIB – Demonstrating MANAC’s technologies by improving DAIM manufacturing

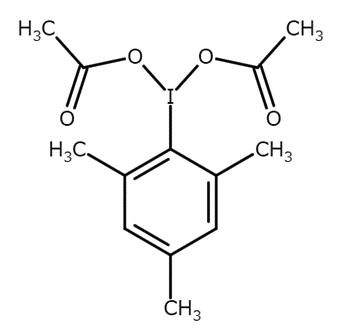

【CAS No.】33035-41-5

【Chemical name】

Iodomesitylene Diacetate

【Chemical formula】C13H17IO4

Did you know there is a particular compound that holds enormous potential despite being relatively unknown?

MANAC has recently improved its manufacturing methods for DAIB, a compound highly sought after as an oxidant in the pharmaceuticals field, allowing the company to provide high-quality DAIB at a low cost. MANAC is currently working toward expanding sales of the new DAIB.

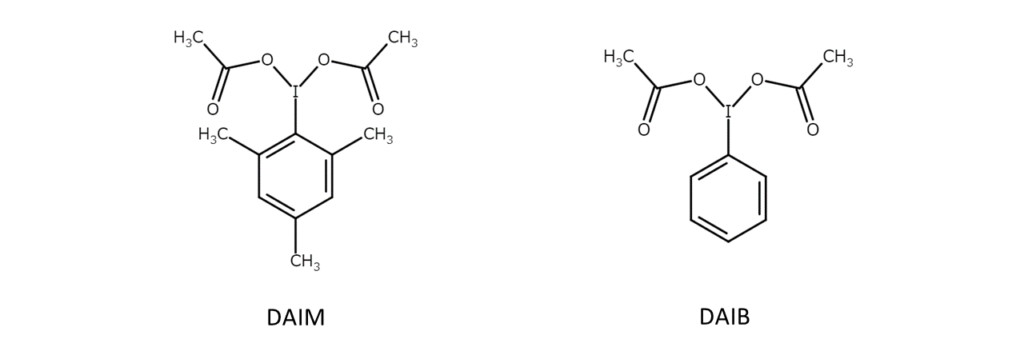

However, DAIB is by no means a universal oxidant. Depending on client needs, there certainly are cases where reactions do not progress favorably using DAIB. In such cases, our next option is to provide candidate hypervalent iodine compounds similar in structure and reactivity to DAIB. One of these candidates is DAIM, a compound for which MANAC is currently working to improve manufacturing methods following similar efforts for DAIB.

Online search engines will only fetch a small number of hits with limited information for DAIM. What kind of applications are anticipated for DAIB’s “trusty sidekick” DAIM, a compound likely handled commercially by only a handful of companies worldwide?

To learn more about the advantages of DAIM and the current state of efforts to improve DAIM manufacturing methods, we sat down with Go Tanaka, who oversees DAIM sales for the Japanese domestic market, and Fumio Kodoi, who is in charge of overseas sales for DAIM.

contents

Introducing DAIM, a DAIB-like hypervalent iodine compound

DAIM is a hypervalent iodine compound with a structure and reactivity similar to DAIB. The formal name of the compound is iodomesitylene diacetate, with other names including 2-(diacetoxyiodo)mesitylene and 2,4,6-trimethyl(diacetoxyiodo)benzene. As with DAIB, DAIM is a useful oxidant in pharmaceuticals and other fields.

To learn more about hypervalent iodine compounds and DAIB, be sure to check the article below.

DAIM is set to appear as the next option for cases where DAIB produces insufficient results. Let’s review what advantages DAIM offers.

In our experience, the first advantage is that DAIM reactions are milder than their DAIB counterparts, making them easier to manage. This property allows for safe reactions and minimizes side reactions.

The second advantage is related to the separation of byproducts. Using DAIB or DAIM in reactions will invariably produce byproducts alongside target products. Distillation or other methods are thus required in order to separate byproducts from target products. In some cases, separation is made difficult by a similar boiling point shared between the DAIB iodobenzene byproduct and the target product. Using DAIM in such cases raises the probability of byproduct separation since the DAIM iodomesitylene byproduct has a significantly higher boiling point than the DAIB iodobenzene byproduct.

A project meant to be: The beginnings of DAIM manufacturing improvement

MANAC has marketed both DAIB and DAIM for many years. However, according to Mr. Tanaka, since both products have similar reactivity and DAIB has been sufficient in most cases, there have only been a few occasions for DAIM to come into play.

“DAIM had always remained behind the scenes. I considered sales of DAIM as occasional strokes of luck.”

However, a turning point would arrive for DAIM in May 2023. Mr. Kodoi was exhibiting at overseas exhibitions when a US manufacturing company representative approached him.

“The manufacturing company was interested in using DAIB for oxidation reactions but struggled to separate the iodobenzene byproduct. The company representative then asked if there might be any promising solutions,” explains Mr. Kodoi.

In response, Mr. Kodoi recommended DAIM. After explaining that using DAIM in place of DAIB may allow for such byproducts to be separated, the manufacturing company representative grew greatly intrigued and expressed a strong interest in receiving DAIM samples. Mr. Tanaka explains that when he heard about this exchange from Mr. Kodoi, he felt the time was right to get serious about DAIM.

“At the time, we had just completed our DAIB manufacturing improvement and were receiving positive feedback from clients. Seeing that we successfully improved our DAIB manufacturing, it seemed highly likely that we could succeed in doing the same for DAIM since it has a DAIB-like structure. With DAIM samples also being provided, I felt we should take the opportunity to improve DAIM manufacturing. Achieving mass production of high-quality DAIM through improved manufacturing methods would also provide the impetus to focus on expanding DAIM sales.”

Thus, the DAIM manufacturing improvement project began. Unsurprisingly, the project would not proceed as smoothly in reality as it would appear on paper. As was the case for the DAIB manufacturing improvement project, scaling the manufacturing process up for DAIM is not quick and easy, and various issues continue to arise.

Mr. Tanaka explains further. “Turning failure into success through persistent dedication is one of MANAC’s specialty areas. I am confident that our researchers in charge of MANAC’s process development will undoubtedly overcome these obstacles and achieve improved manufacturing methods in order to meet client needs.”

Using DAIM to realize an eco-friendly society

In light of the growing focus on the environment in recent years, DAIB and other hypervalent iodine compounds have been gaining attention in various fields as alternative oxidants to conventional heavy-metal-based oxidants. Mr. Tanaka explains that he anticipates this as the main target for DAIM.

“Without a doubt, some companies wish to switch their oxidants to something like DAIB but are stuck using heavy-metal-based oxidants due to difficulties with DAIB in their specific applications. Once we can present DAIM as the next option to these companies, I believe many of them will be able to switch to DAIM without issue.”

Once the DAIM manufacturing improvement succeeds and mass production is achieved, MANAC will be able to provide DAIM to even more clients, allowing MANAC to contribute toward realizing an eco-friendly society free of heavy-metal-based oxidants. At present, MANAC is taking a major turn toward such a future, as Mr. Tanaka adds.

“Once we achieve improved DAIM manufacturing methods, we aim to widely promote MANAC’s high-quality DAIM globally so that it becomes well-known among many companies.”

MANAC’s new DAIM appears to be making significant strides toward a promising market launch in the near future. There is much anticipation for DAIM to be a ground-breaking solution for the many companies struggling with DAIB applications. MANAC will continue to strive in the manufacturing and marketing of DAIM.