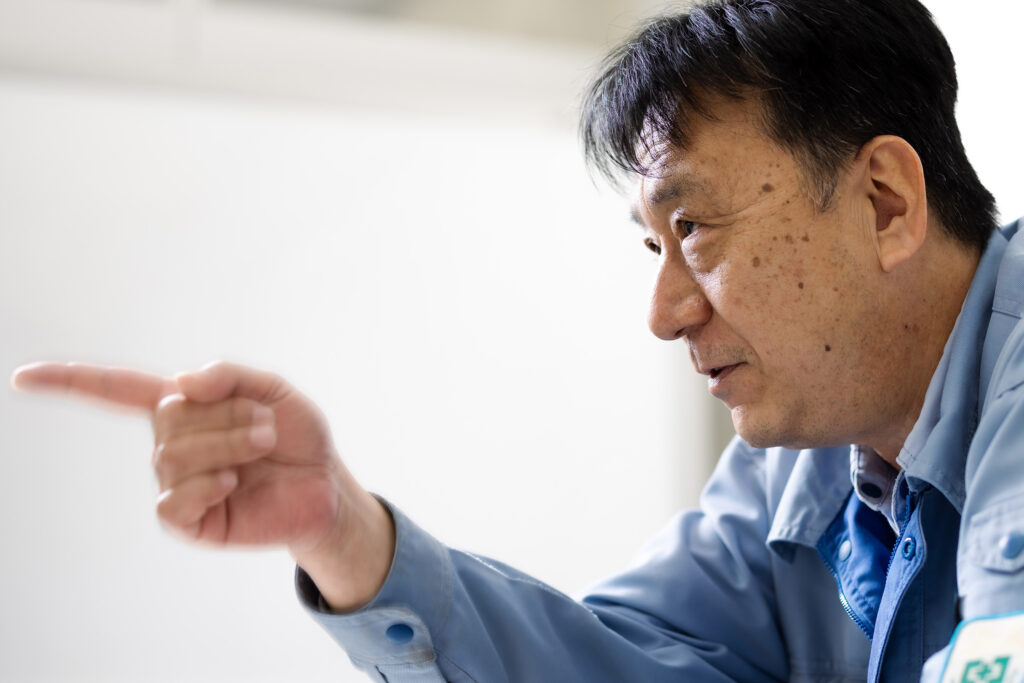

The secret behind “MANAC is bromine”/Defining what should be passed on to the next generation, as told by Fukuyama native factory chief

MANAC boasts the number one spot as a manufacturer of chemical intermediates for the amount of bromine consumed domestically in Japan. Because bromine requires a very high level of caution, the number of companies that handle the chemical is on the decline. This is despite the fact that bromine is used in a large variety of chemical reactions. What lies behind MANAC’s ability to handle bromine is that the company is well versed in the handling of bromine. We sat down with Mr. Atsushi Sakabayashi, chief of Fukuyama Factory, to learn about the secret behind this success.

■ What you can learn from this article ✔ MANAC uses liquid bromine instead of powder to enable a wider range of chemical reactions. ✔ At MANAC’s Fukuyama Factory, each building is equipped with alkali removal towers that absorb and neutralize bromine substances to prevent health hazards caused by bromine vapor. ✔ Passing down veteran employees’ knowledge to the next generation is a crucial task for maintaining safety. ■ Recommended Articles ・ From OLED to solar batteries, functional materials, and semiconductors, as told by the famous “catcher” of contracted research: “The difference between me and AI” ・ Making complex compounds a breeze! The heterohalogen series ・ Tight clean room management:“I want to oversee a new active pharmaceutical ingredient from formulation through to manufacturing” – From the factory floors of intermediates for new drugs (Part 2)

contents

Nothing more than a simple liquid from the viewpoint of younger workers

“Bromine is what you would call a hazardous material.”

“Those who have been here (at MANAC’s Fukuyama Factory) since the old days know the dangers of bromine.”

“Nowadays, it’s a given that bromine is kept from leaking out, so I guess from the perspective of a younger worker who has never experienced these dangers, it probably looks just like any other liquid.”

Mr. Sakabayashi, born in Fukuyama, began explaining with a colorful sprinkling of the local Fukuyama dialect.

Bromine is highly reactive and used for oxidation, additives, replacement reactions, and other applications. Synthesized bromine compounds are used in a wide range of usages, including intermediates for electronic materials and pharmaceuticals. However, bromine produces a harsh, pungent odor and can result in death in the worst cases if vapors are inhaled in large quantities.

Why is it that MANAC continues to use bromine amid an increasing number of companies avoiding handling highly toxic compounds?

“Bromine reagent powders are very easy to handle, but the chemical reactions that can be achieved with powder bromine reagents are limited. Using bromine allows for a larger range of chemical reactions, and with that, an increased variety of products, all at a low cost. The ability to use bromine is a strength of MANAC.”

Alkali removal towers installed at six factory buildings

“Well, I can’t really explain very well just how MANAC excels in its handling of bromine…” explains Mr. Sakabayashi before continuing further.

MANAC’s Fukuyama Factory has six factory buildings, each fed directly through pipelines from a large bromine storage tank. This enables immediate access to bromine whenever needed for carrying out chemical reactions at the factory. In the past, the material used for piping was typically lead. In recent times, however, this is shifting toward resin-lined piping.

“Lead piping is difficult to process, and nothing can be done about its degradation over time. Resin-lined pipes aren’t invincible either, but the degradation they undergo can be addressed. Having piping connected directly to each factory building is a strength and puts MANAC at an advantage, although maintaining it is very tough. We are constantly keeping an eye on the timing for periodic inspections and replacing parts. Oh, and also, the fact that bromine is highly volatile presents quite the challenge.”

Since bromine readily vaporizes, even leaks of minuscule amounts pose a risk to the health of workers in the factory. For this reason, MANAC has introduced a system to eliminate the harmful effects of bromine with alkali removal towers installed at each factory, which absorb and neutralize bromine substances.

With consideration to environmental impacts, the hydrobromic acid that occurs as a byproduct during bromination reactions is used to manufacture certain inorganic bromides. Inorganic bromides have several applications, including in pharmaceutical substances.

My heart jumps whenever I get a call on days off!

Mr. Sakabayashi majored in biochemistry at university and has worked at MANAC ever since first joining in 1986. Immediately after joining the company, Mr. Sakabayashi was first involved in establishing drainage facilities. He then continued work in research to meet the needs of projects commissioned from companies, becoming factory chief in 2017.

While there have not been any major accidents in the past five years involving bromine leaks, according to Mr. Sakabayashi, the reality is that the number of incidents is not a clean “zero.”

“My heart jumps whenever I get a call at night. MANAC factories operate on weekends too, and I just can’t help but think, “oh no, is there a bromine leak at the factory!?” whenever I get a call during the weekend.”

Periodic inspections of the equipment needed to use bromine must be consistently and reliably carried out to ensure safety. Mr. Sakabayashi further elaborated.

“I believe that the kind of things that are a given for long experienced employees may be essential as knowledge in handling bromine. Passing this knowledge in full to the next generation of workers is an important job for my generation. The measures we have now for the COVID-19 pandemic mean we have fewer opportunities to communicate across different generations of workers. I wonder if we can’t manage to find a good solution. I think it’s important that we can handle this even during such times.”

MANAC’s factories operate 24/7, continuously producing a wide variety of chemical intermediates.