Achieving both high added value and low waste: Overcoming the “high hurdle” of flow synthesis with bromination!

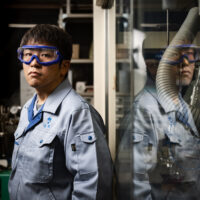

Bromine is used to create compounds with a wide range of characteristics by binding molecules together. For this reason, bromine compounds are widely used in the chemicals industry across many fields. However, in addition to being highly corrosive, bromine presents challenges in handling it for industrial-scale use as it also acts as a strong oxidizer, is very volatile, and is highly reactive. As bromine can be harmful to human health, there are chemical companies that avoid bromine reaction processes. Manac is currently looking to use its glass lining reactor of up to 10,000 liters for large-scale bromine reactions and further develop bromine reactions with the flow synthesis method, which continuously reacts substances with small amounts at a time. The company has started experiments to produce high-purity compounds using bromine reactions only possible with flow synthesis. We spoke with Satoshi Murakami, who is researching this method.

■ What you can learn from this article ✔ Flow synthesis reduces the risk of runaway bromine reactions, enhancing safety. ✔ Flow synthesis minimizes waste and purification effort, making it eco-friendly. ✔ Manac’s expertise with bromine allows them to create high-value-added compounds. ■ Recommended Articles ・ Patent: Solving a pharmaceutical manufacturing company’s challenge with 2-alkoxyethyl bromide that can undergo long-term storage ・ Achieving high purity, cost reductions, and GSC / At the forefront of bromine microflow synthesis research ・ Active/inactive aromatic ring bromination: Bromination reactions that use NBS (2): N-bromo compounds (4): Discussion series on bromination/iodination reactions 4

contents

Safe for the environment and human health

Roughly 99% of chemical products are produced through batch synthesis, which places all the raw materials into a large glass lining reactor and reacts them together all at once. When using batch synthesis to combine raw materials A and B to produce compound C, the reaction will leave not only the targeted compound C within the vessel, but also extra compounds D and E. This necessitates purification work such as recrystallization in order to extract the C compound. While batch methods enable mass production, they entail disadvantages such as labor requirements and costs for purification and large amounts of waste materials produced after purification processes.

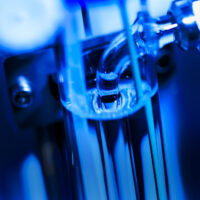

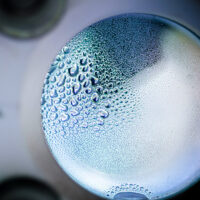

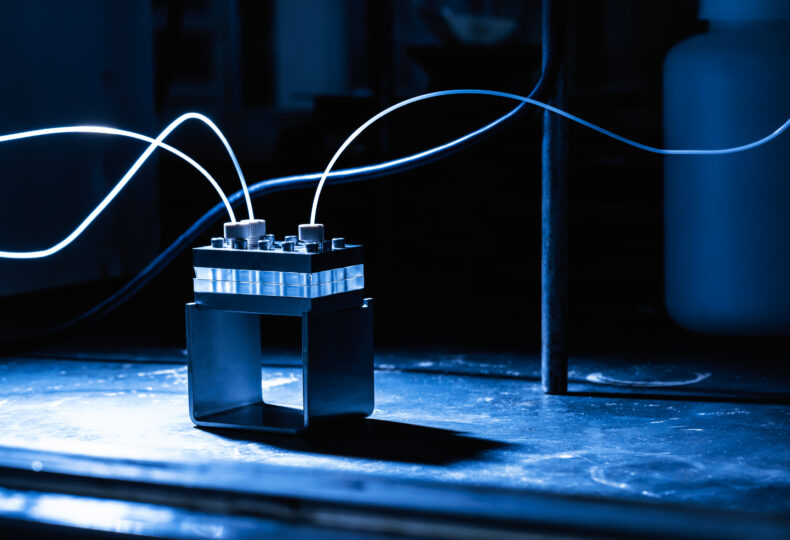

Flow synthesis is the answer to these problems. In flow synthesis, raw materials are continuously pumped in small amounts into a tube, where chemical reactions are well controlled as the materials flow through the tube, resulting in only the targeted compound by the time the liquid flows out. As this reaction process significantly reduces purification labor needs and waste over batch methods, flow synthesis also offers an advantage in safety for the environment and human health. Large equipment is also unnecessary.

The challenge of making bromine reactions possible in flow synthesis

There is yet another advantage to using flow synthesis for bromine reactions. Since flow synthesis minimizes the risk of runaway chemical reactions, there is little risk of the process becoming harmful to human health, making it very safe.

However, bromine is much heavier than water, and is a highly corrosive substance, so adaptations are needed in the equipment used. It is also difficult to control the amount of material that flows into tubes, and so the hurdle to the industrial use of flow synthesis with bromine has been said to be high.

Continuously seeking methods to produce chemical products as requested from several companies, Mr. Murakami’s work has begun to pay off. “As of now, we can achieve reactions as they were predicted.” Mr. Murakami’s journey to seek such methods continues as he follows his grandfather’s teachings. “Don’t leave things on paper, test anything and everything. Taking action will always lead to something new.”

The road to beating the competition in fine chemicals

Chemical products from high-mix, low volume (HMLV) productions are known as fine chemicals. These chemical products feature complex molecular structures and have high functionality and added value. The market for fine chemicals is growing with usages across various fields, including for raw materials used in electronic components, pharmaceuticals, food, agrochemicals, and flavorants. This is a focus area for many chemical companies.

Although large equipment and facilities are not needed for HMLV, experiments must swiftly be conducted countless times over in order to produce a high mix of products. We will come out on top over other companies in the race to develop by using flow synthesis to produce fine chemicals. That is our aim here at Manac.

The future of flow synthesized bromine compounds

We asked Mr. Murakami about the current situation.

Have you shipped out any of your compounds as products?

We haven’t reached commercialization for any products yet, and are at the testing stage to confirm what kind of compounds can be produced. Compounds that differ from anything ever made before at Manac, and can only be made through flow synthesis, are being achieved.

What kind of advantages does Manac have over the competition in producing bromine compounds with flow synthesis?

Our company has been using bromine for many years, so our advantages lie in the expertise we amassed for the proper handling of bromine in addition to our full line of equipment and facilities necessary to handle bromine appropriately. I believe that if we effectively apply these advantages, we can make high value-added, high-purity compounds only possible at Manac to meet a wide range of customer needs.