New business with diiodomethane – Aiming to realize SDGs by targeting API manufacturers with proprietary cyclopropanation reactions

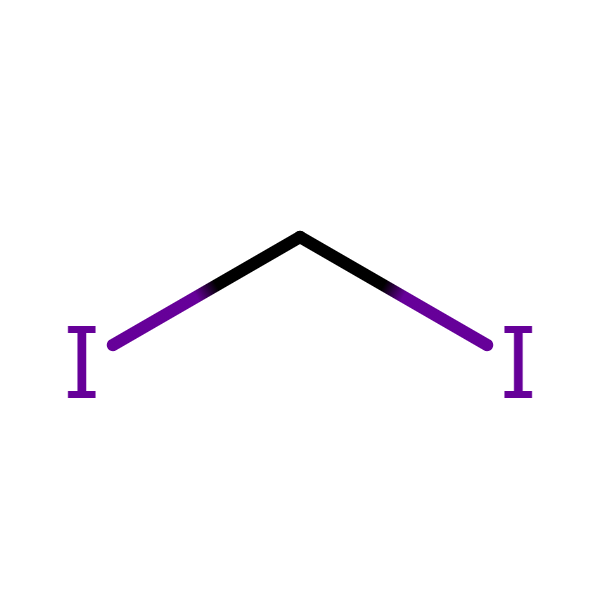

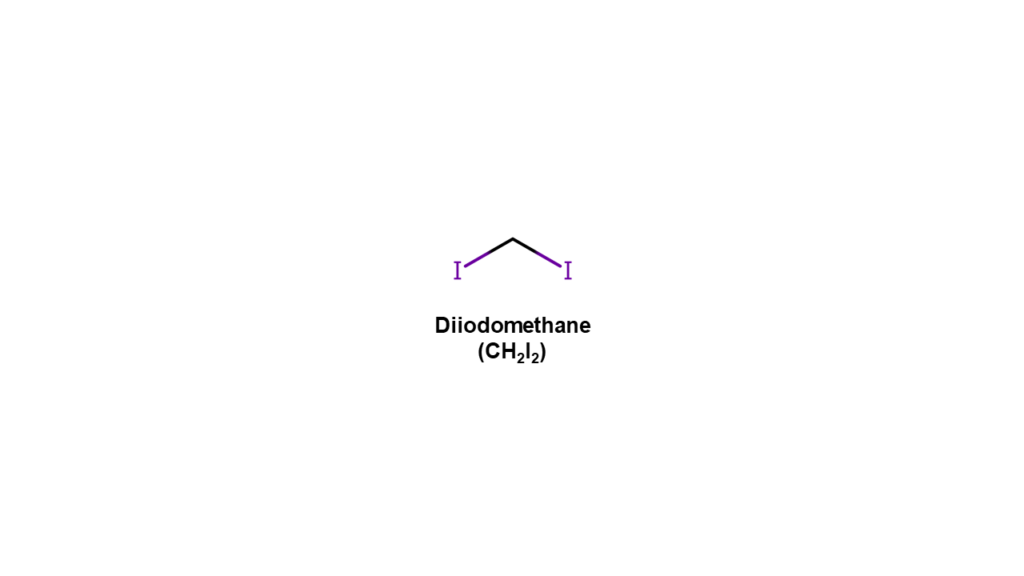

【CAS No.】75-11-6

【Chemical name】Diiodomethane

【Chemical formula】CH2I2

In addition to contracted research, Manac also actively develops its own original technologies. The company does this with the aim of providing new value to society by combining its technical expertise cultivated over the years with market trends.

Out of the original technologies Manac is working to develop, there is a certain new technology for which development began in FY2018 and has just started being presented to other companies as of FY2019. To learn more, we sat down with Hironori Takeda, Team Leader of the Researchand Development Center’s Pharmaceutical Team, overseeing the development of this technology at Manac.

■ What you can learn from this article ✔ Manac actively engages in developing its own technology. ✔ They target API manufacturers and built a one-stop business model for cyclopropanation. ✔ Iodine recycling is conducted with partner companies, considering sustainability. ■ Recommended Articles ・ The art of controlling unexpected runaway chemical reactions — “young artisan” of contracted research taking on the challenge of developing pharmaceutical materials ・ Iodoalkane synthesis: Iodination reactions with halogen exchange (2): Discussion series on bromination/iodination reactions 13 ・ Alkane iodination: Aliphatic compound iodination overview and reactions: Aliphatic compound iodination reactions (1): Discussion series on bromination/iodination reactions 18 ・ Iodoalkane synthesis from alcohols: Iodination reactions using alkali iodides (2): Discussion series on bromination/iodination reactions 25

contents

It all started with Manac’s own diiodomethane

Manac has long been manufacturing and marketing a compound known as diiodomethane. The compound contains two iodine (I) atoms, and its basic structure is illustrated below.

As Mr. Takeda explains, “In considering new technologies that utilize our diiodomethane compound, we investigated what fields require the use of diiodomethane. During this process, cyclopropanation reactions caught our attention.”

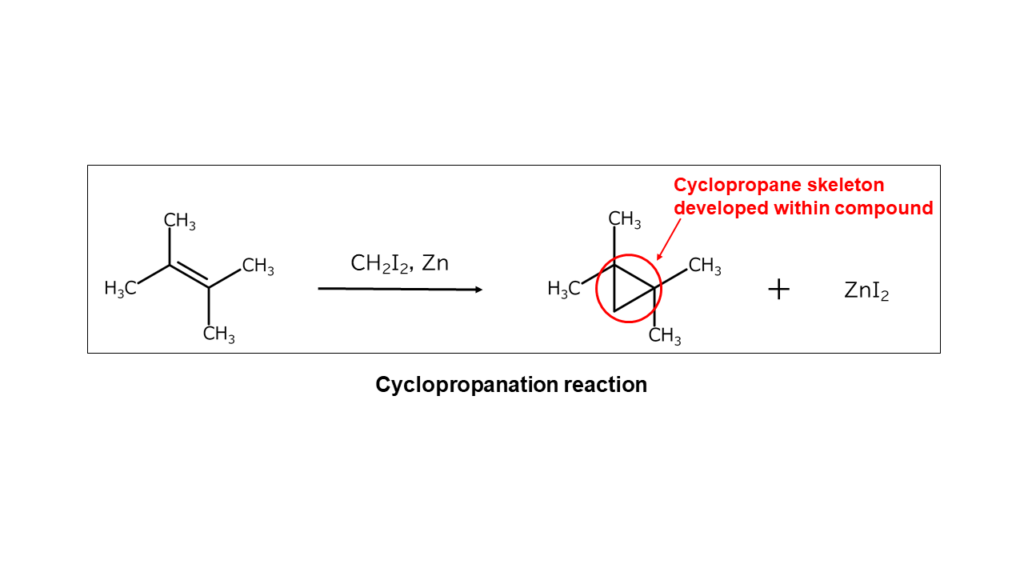

When diiodomethane reacts with other compounds, that compound develops a triangular structure known as cyclopropane (cyclopropane skeleton). This is called a cyclopropanation reaction.

There is sure to be a demand for the diiodomethane that cyclopropanation requires in fields that regularly use compounds with cyclopropane skeletons.

Targeting manufacturers of drug raw materials

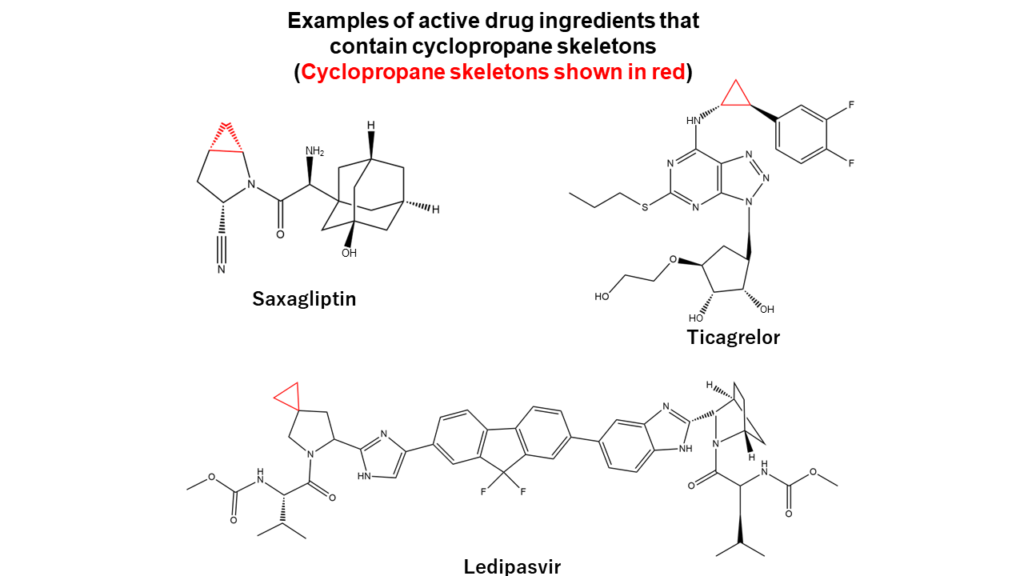

In his market research, Mr. Takeda found that the raw materials of pharmaceuticals (active ingredients) often contain cyclopropane skeletons.

Note: Cyclopropane skeletons are used in various drugs API. Saxagliptin is used for diabetes, ticagrelor for myocardial infarction, and ledipasvir for the treatment of hepatitis C.

In general, the active pharmaceutical ingredients(API) of drugs exert their therapeutic efficacy by binding to specific parts of targeted proteins.

In order to effectively bind API to targeted proteins, specific adjustments must be made to the structure of the API. Creating a cyclopropane skeleton within the structure of API makes it easier to achieve these structural adjustments. In addition, as these cyclopropane skeletons are small structures, they do not get in the way when API bind to proteins. There are many benefits to making cyclopropane skeletons in the API of drugs, which became the focus for Mr. Takeda’s team.

“Since manufacturers of API are likely using cyclopropanation reactions to create cyclopropane skeletons, we set our sights on such manufacturers as the main target of this technology. We built a business model that not only provides diiodomethane, but also handles cyclopropanation reactions in one package.”

Working together with a partner company to recycle iodine byproducts

There is one other major part to this story, and that is the recycling of the iodine that occurs during cyclopropanation reactions.

When using diiodomethane to carry out cyclopropane reactions, iodine atoms separate from the diiodomethane compound. This iodine ends up as zinc iodide in the resulting waste liquid, and as Mr. Takeda explains, how this waste liquid is handled is of great importance.

“The disposal of waste liquids that contain iodine incurs high costs. In addition, with calls for chemical recycling and Sustainable Development Goals (SDGs), methods that produce things and throw out the rest are not ideal. There was no way to avoid the issue of iodine recycling in the promotion of this new technology.”

Manac’s partner company in the iodine field, Godo Shigen, possesses a proprietary technology to recycle the iodine contained in waste liquids. By utilizing this technology in collaboration with its partner company, Manac now offers a full package that includes the collection of iodine from the waste liquids formed during cyclopropanation reactions.

“However, we can’t recover iodine from waste liquids if the concentration of iodine is too low, and there are certain waste liquid substances with inseparable iodine. We must make waste liquids from which iodine can be recovered. This might be achieved through adjustments in the timing and amounts of added raw materials during cyclopropanation reactions, as well as finding the appropriate types of solvents to use. The knowledge we have amassed at Manac is also being applied in this process.”

As such obstacles are overcome, recovered iodine is then used to create new iodine compounds.

A research environment that promotes technology seeds

As Mr. Takeda explains, one of the unique advantages of Manac is its ability to carry out both contracted and original technical development.

“Manac takes on a lot of contracted research, but it also encourages the submission of ideas for new technologies internally. This new cyclopropanation technology also got its start from a certain researcher’s idea. We routinely ask younger workers to keep their eyes open for new leads.”

Seeds for the next new technologies are already sprouting from within Manac.