Major use in various fields! Three polyimide monomers manufactured by Manac

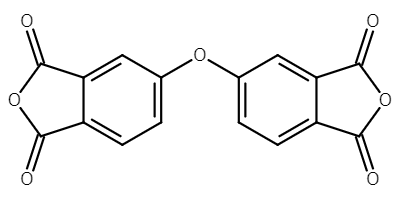

ODPA-C

【CAS No.】1823-59-2

【Chemical name】 4,4′-Oxydiphthalic anhydride

【Chemical formula】C16H6O7

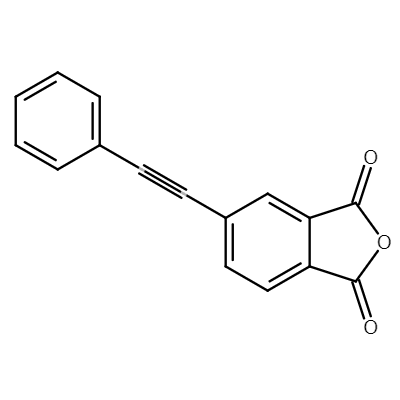

PEPA

【CAS No.】119389-05-8

【Chemical name】4-Phenylethynylphthalic anhydride

【Chemical formula】C16H8O3

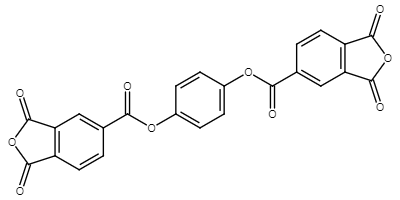

TAHQ

【CAS No.】2770-49-2

【Chemical name】 5,5′-[p-Phenylenebis(oxycarbonyl)]diphthalic anhydride

【Chemical formula】C24H10O10

Manac manufacturers resin raw materials (monomers) known as polyimides. Polyimides excel in various properties, including strength and heat resistance, making them highly versatile.

Each of the three types of polyimide monomers that Manac manufactures and markets is difficult to manufacture, and no other company manufactures them in Japan. Just what kind of compounds are these polyimide monomers that sit at the pinnacle of technical prowess?

■ What you can learn from this article ✔ Manac is the only company in Japan manufacturing three types of polyimide monomers. ✔ ODPA-C allows light to pass through easily and is used in semiconductor protective coatings. ✔ TAHQ polyimide plays a critical role in high-frequency circuit boards in the 5G era. ■ Recommended Articles ・ Playing a major role in the 5G era! The TAHQ polyimide monomers expected to be used for high-frequency circuit boards ・ Responsibility and accomplishment as the engine of work / the younger members of the pharmaceutical manufacturing team (1) ・ Opportunities await us in the bromine and iodine domains / Manac’s growth strategy as told by President Murata

contents

What are polyimides?

Resins such as polyimides are formed with a long chain of small compounds called monomers.

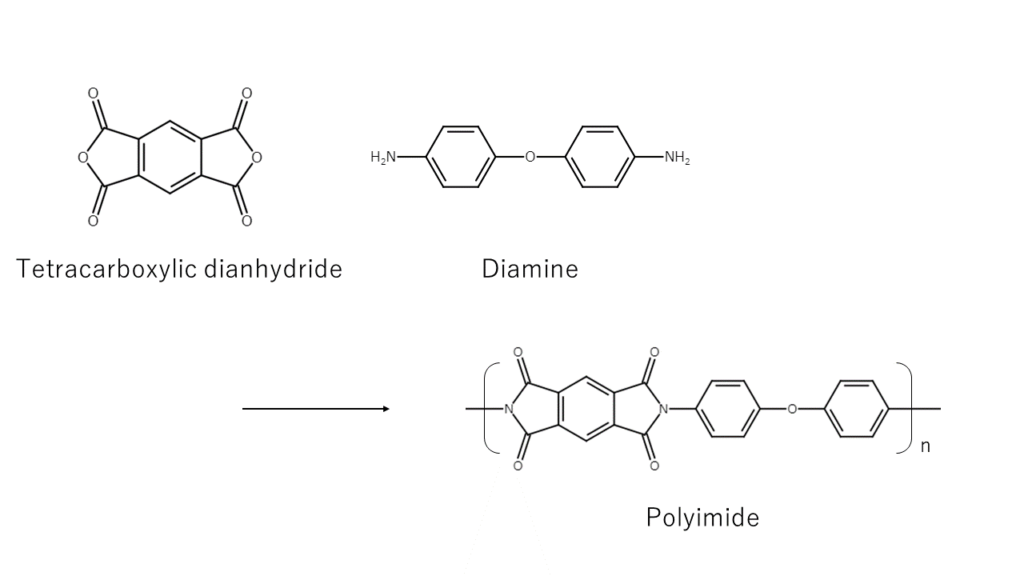

Polyimide resins are formed by bonding, in alternation, two types of monomers called tetracarboxylic dianhydrides and diamines, such as those shown below. There are various types of both tetracarboxylic dianhydrides and diamines, and the resulting polyimide structure changes depending on the monomers used (the reaction formula below is one example).

This section introduces the three types of polyimide monomers that Manac manufactures and markets, as well as their structures, characteristics, and usages.

Major usage in the semiconductor field! More than 30 years of ODPA-C history at Manac

ODPA-C is a polyimide monomer that Manac has been manufacturing since more than 30 years ago and has the longest history at Manac among the monomers being introduced in this article.

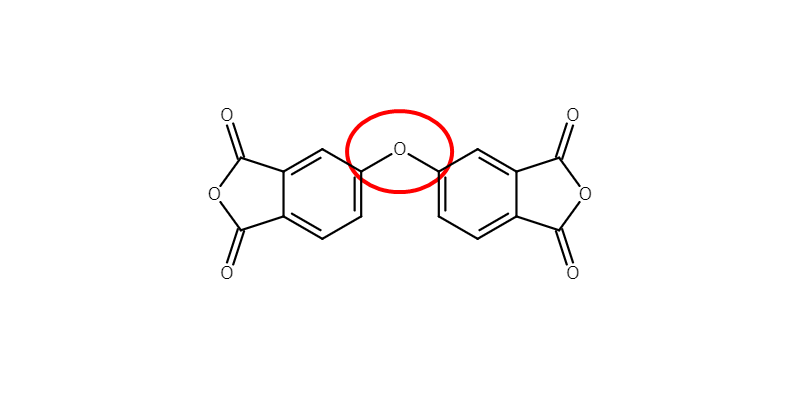

ODPA-C features an oxygen atom (O) in the middle that serves as the bond portion (circled red in the diagram above). This bond is known as an ether bond.

Although standard polyimides are dark brown in color, the ether bonds present in polyimides made from ODPA-C (ODPA-C polyimides) result in a lighter color. Making the color lighter allows more light to pass through in comparison to standard polyimides.

A major application of ODPA-C polyimides is in protective coatings for semiconductor circuits.

When making semiconductor circuits used in electronics such as personal computers, various materials are layered on top of a base material while shaving out specific areas within the layers. A film known as the protective coating is then required to be applied over the top layer of the circuit for protection. ODPA-C polyimides, which allow light to pass through, are used for such protective coatings.

Why is it important to allow light to pass through the protective coating?

When manufacturing electronics, certain semiconductor circuits are often connected with other circuits. This requires a hole to be made in the protective coating for wiring. However, in mechanical terms, removing a portion of the coating is an extremely difficult task.

Using such ODPA-C polyimides with photosensitivity (the quality of having structural changes with exposure to light) in the protective coating allows for precise holes to be created with simple, targeted exposures to light. Since the shape of these holes cannot be accurately controlled unless the light can fully penetrate through the protective coating, ODPA-C polyimides are treasured as protective coating material with their ability to allow light to pass through.

Also, a polyimide monomer with a slightly asymmetric ODPA-C structure is also used for the IKAROS sailing spacecraft.

The key is in forming the mesh structure! The use of PEPA for super heat resistance

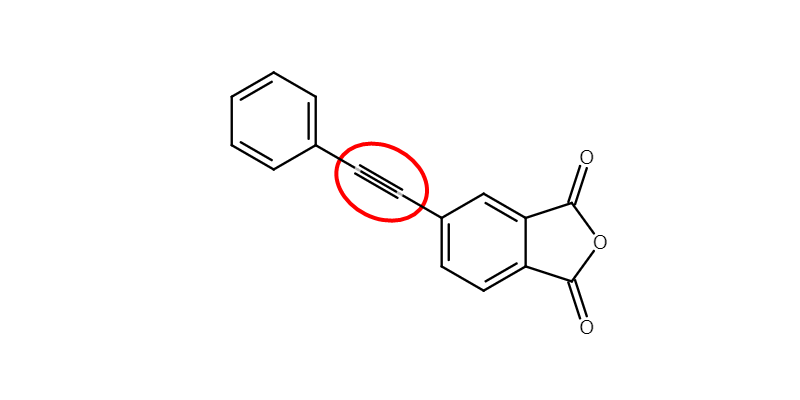

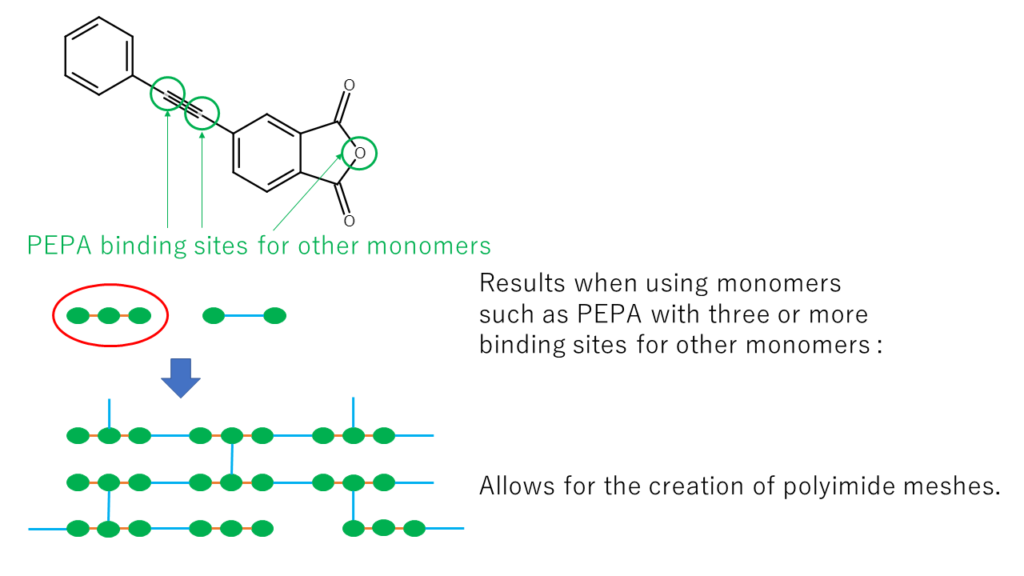

PEPA monomers have a structure such as that shown in the diagram above. The defining feature is in the triple bond between the molecules (circled red in the diagram above).

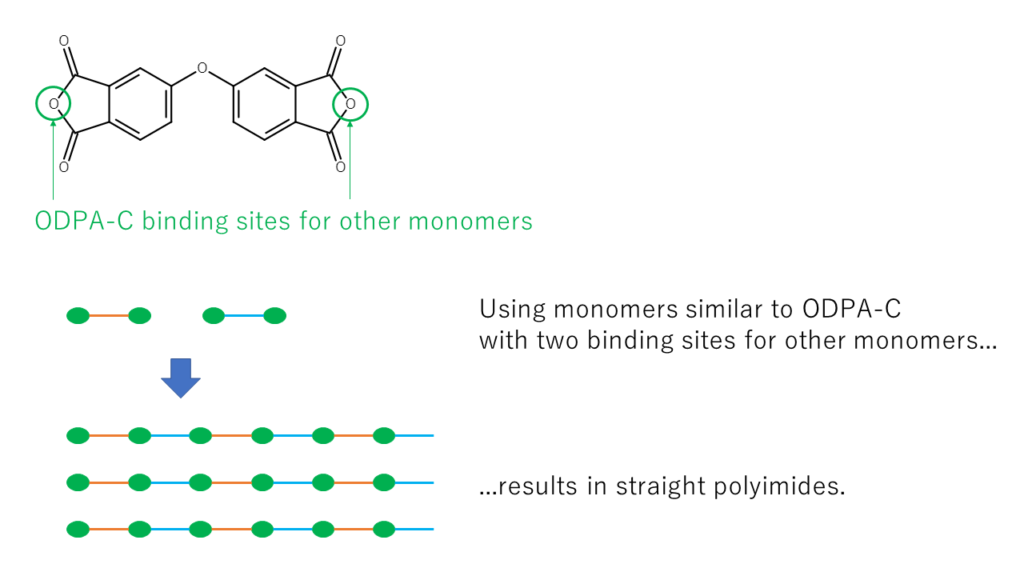

Most polyimide monomers outside PEPA have only two sites for other monomers to bond. For example, ODPA-C has two sites, as shown in the diagram below. Using such monomers results in straight, branchless polyimides such as the diagram below.

In contrast, using PEPA generates polyimides with a mesh structure. This is made possible by the three or more monomer binding sites that PEPA possesses, as shown in the diagram below.

Mesh polyimides have a higher heat resistance than polyimides with a straight structure. For this reason, polyimides made from PEPA are used as “super heat-resistant materials” in many different fields. PEPA monomers are even used in the exhaust components of aircrafts.

A key player in the 5G era! The characteristic low water-absorption rate and low thermal expansion coefficient of TAHQ

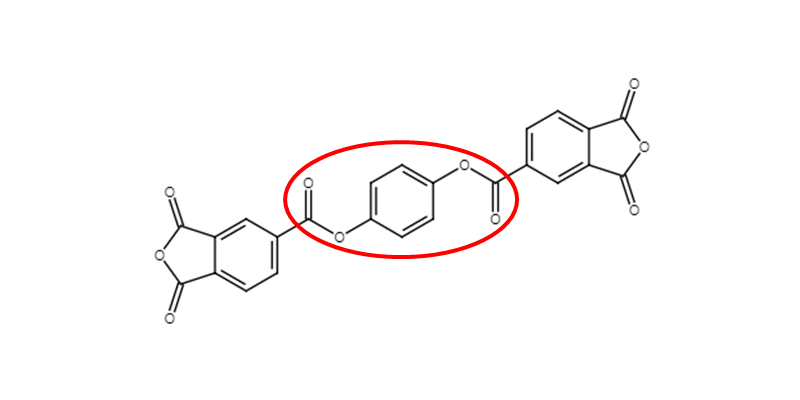

The diagram above depicts the structure of TAHQ monomers. Manac has been manufacturing TAHQ since approximately 20 years ago.

The most defining characteristic of polyimides made from TAHQ (TAHQ polyimides) is a low water-absorption rate. While general polyimides have a water-absorption rate of up to around 3%, TAHQ polyimides have an impressive absorption rate of less than 1%. This is believed to result from the benzene ring and ester bond (-COO-) in the center portion of TAHQ (circled in red in the diagram above).

Recently, these TAHQ polyimides have come to hold much promise for use in 5G high-frequency circuit boards.

High-frequency circuit boards are required to transmit signals quickly. However, if the circuit board materials have a high water-absorption rate, the materials can have a negative impact on signal transmission due to the absorption of a lot of moisture. Materials such as TAHQ polyimides with a low water-absorption rate are required for high-frequency circuit boards to avoid this issue.

Digitalization will only continue to advance in the world. TAHQ will likely draw attention as it plays a major role in the 5G world.

The polyimide market will continue to expand

Manac’s polyimide monomers have applications in various fields, including semiconductors, heat-resistant components, and high-frequency circuit boards. In particular, the demand for TAHQ will likely further expand with the development of telecommunications technologies.